How Robotic Fulfillment Technology is Changing The Supply Chain

Autonomous robots and robotics in warehouse management can perform tasks with little or no human intervention. They can vary significantly in size, functionality, mobility, and cost, from robotic fulfilment systems in processing plants to flying drones that can take stock inventory in a matter of minutes. Increasingly the applications of warehouse robots programmed with artificial intelligence are becoming a significant part of a company’s supply chain. Now they can recognise and learn from their surroundings, make decisions independently and streamline the majority of processes efficiently. Warehouse robotics companies are bringing new and innovative methods for improving the supply chain and delivering significant value to a wide variety of different sectors.

Supply Chain Automation Trends

Automation, especially involving robotics in warehouse material handling, has seen growth recently and this trend is only set to increase in the years to come. This will also apply to jobs that involve repetitive actions, are viewed as being potentially dangerous or of a particular high-risk to humans. Robotic fulfilment is already utilised by manufacturing companies regarding final assembly and warehousing.

Autonomous robots will be more involved in the supply chain of the future as advancements will give them more human-like abilities. Improvements in their sense of touch will allow robots to grasp objects ranging from the fragile to the multi-surfaced to objects that are too hot or cold for humans to grasp safely.

As they become more sophisticated, setup time will decrease, they will require less supervision, and will be able to work seamlessly alongside humans. The benefits are expanding as autonomous robots become capable of working independently around the clock with more consistent levels of quality and productivity, performing tasks that humans cannot, should not, or would not want to do.

Pros and Cons of Using Robotic Technology in the Retail Supply Chain

Autonomous robots can help spearhead advancements in the supply chain and add value by reducing operating costs as well as increasing potential revenue. More specifically autonomous robots can add support with:

- Increasing overall efficiency and productivity

- Reducing the error, re-work, and risk rates

- Improving employee safety

- Performing low value, mundane tasks so humans can focus on more strategic efforts which are unable to be automated

- Improving order fulfilment rates, delivery speed, and customer satisfaction

- Minimizing work in hazardous areas or high-risk environments

- Boosting the perception of your company as cutting-edge and a user of innovative technology

- Improvements can continually be made and assesd through collecting and analyzing machine data

Now that we’ve outlined the benefits, it’s important to consider the drawbacks that can come from replacing human workers with machines.

Job Elimination: Robots won’t stimulate job growth in a warehouse. Workers may find their jobs eliminated, especially as technology improves and robots are able to take on more and more complex tasks.

Limited Adaptability or Ingenuity: While workers can analyze situations and use their ingenuity to find solutions to problems, robots are not as adaptable to change. A robot is only able to follow the programming that has been coded into its system.

Substantial Monetary Investment: Initial and ongoing costs can simply be a lot for warehouses to take on. Bringing in robots can lower labour costs but paying for maintenance and programming can be expensive. Since skilled robotics programmers are scarce, a company can find themselves paying a lot regarding maintenance.

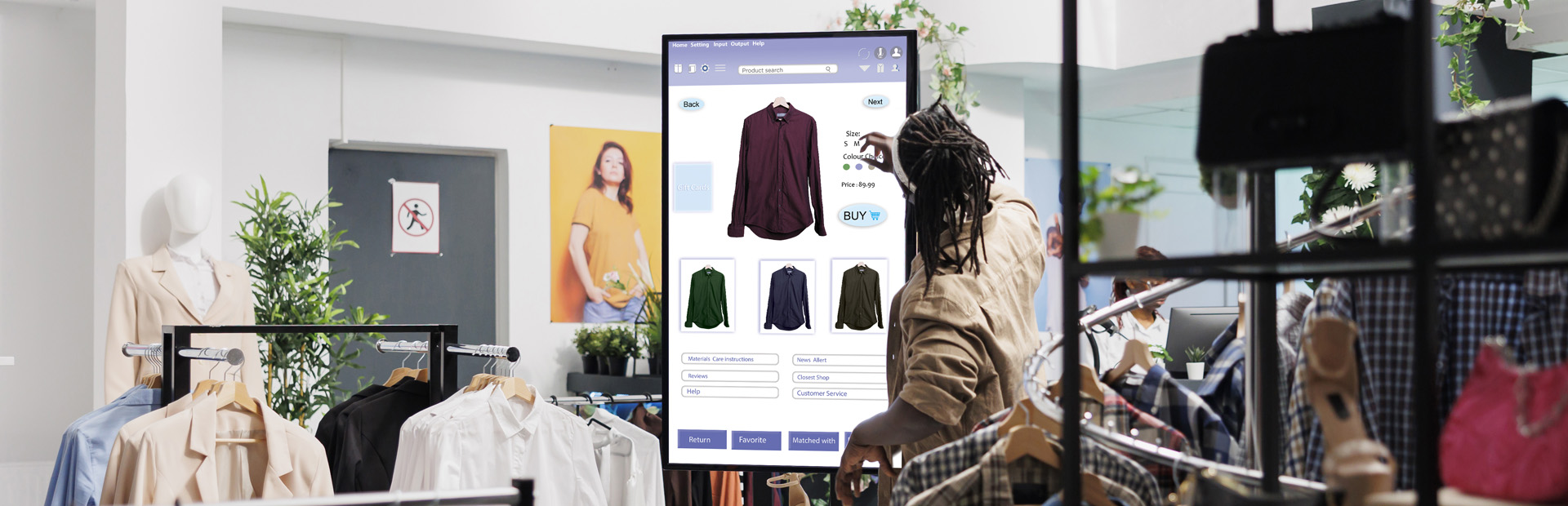

Retail Brands Using Robotic Fulfilment

Retail marketing automation is seeing more and more usage and many companies are now integrating it into their company setup in a variety of different ways and manners. Some businesses that have been implementing it effectively include:

Best Buy: Best Buy have begun testing a product-retrieving robot named Chloe. This can retrieve small items such as CDs, boxed products and headphones in a matter of seconds following a complete purchase on a touchscreen.

Walmart: Walmart is testing warehouse drones that monitor inventory levels and can flag low stock or missing items. The efficiency of these drones in unparalleled as they can perform a full stock check-in under a day, something that would usually take a human around a month.

Lowe’s: Hardware store Lowe’s recently introduced a team of ‘Lowebots’ at 11 stores in San Francisco. The multilingual bots help customers locate products and monitor inventory levels in real-time.

Amazon Supply Chain Management

Amazon fulfilment centre technology is arguably the one that is being used with the greatest efficiency. In an Amazon warehouse their robots can pick and pack products without needing human assistance, streamlining all warehouse activities incredibly efficiently. Since 2015, Amazon has increased warehouse robots by 15,000 each year and currently has 45,000 warehouse robots in operation.

At the present time, Amazon’s robotics have been aimed at bringing goods to people for the picking of orders. Moving forward they will likely be able to pick their own orders, reducing the need for human order pickers in the supply chain.

What Next For Supply Chains?

The time for companies to assess their supply chains in regards to autonomous robots is now. Depending on needs and existing capabilities within the supply chain, implementing autonomous robots can provide improvements in both productivity and efficiency. Alongside this it can also reduce labour costs, improve employee safety and increase customer satisfaction. Technology will improve, autonomy will become more prevalent and and prices will decrease meaning it’s no longer whether autonomous robots will be involved in supply chains of the future, but how soon before they become an everyday feature throughout industries.

Subscribe To Us

Our Services

Categories

Subscribe To Us

Contributors

Categories

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. Third party cookies such as Google Analytics is also used on this site to provide analytics in order to better understand the user engagement on our site.

You can adjust all of your cookie settings by navigating the tabs on the left hand side.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

0.Comments